3 has to pass around. Hollow Turning Vane and Vane Rail are designed to redirect the air through elbows and tees in the ductwork without significant loss of air pressure.

Turning Vanes Sheet Metal Journal

Turning vanes assist the airflow in making a smoother and more gradual change in direction thus transferring less impact and less force to the duct walls.

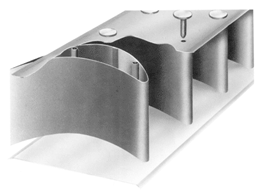

. Turning vanes are comprised of the vane rail 2 which comes in coils 1 and the turning vane 3. Duct and fittings have interconnecting ends that lock together with brackets. 83 Reducing Trunk System.

Flexible duct flexible connection. With Aero Dyne Turning. This fitting will add 25 to the TEL.

As you can see this particular vane is a double wall vane that is mounited to the duct via a rail assembly. Tending from the rear wall and out through the elbow exit is a rotor-bearing housing followed by a simulated rotor hub which results in an annular area at the exit of the elbow. 82 Reducing Plenum System.

These features make it possible to actually get into and out of the ductwork. When airflow changes direction in a duct that lacks turning vanes the walls of the duct must absorb the sudden impact of the air in order to reorient the airflow to the direction desired. While turning vanes are a small component within the overall system they can play a vital role in reducing noise while increasing efficiency throughout the system.

The use of turning vanes provides for better air flow and fluid dynamics. Control exhaust or return air inlet ceiling indicate type supply outlet. The types of fittings to be used based on the designers calculations of fitting losses ie square versus 45.

To gain some insight into this lets consider a 12 square elbow with a 12 centerline radius ie. The centerline radius is equal to the duct width like the one pictured below. The link takes you to a specification sheet for this product that will show you.

A quick Google search can. Leakage rate at the test pressure. The Original Clamp-Together Ducting.

Ad Order Online - Speak with an Expert - Fast Delivery - Lowest Prices. Supply grille sg return rg or exhaust eg grille note at flr of clg supply register sr a grille integral vol. 86 Perimeter Loop System.

Kitchen exhaust ducts also are free from any obstructions in the ductwork. These can be fabricated at any sheet metal shop. The ducts also have access panels for cleaning.

For those who have never actually seen turning vanes here is a picture of an elbow before it was installed on a recent project. Turning vane directs airflow around corners. The square ell can be improved substantially with the addition of interior turning vanes.

These Vanes are usually cut on a chopsaw from 10 ft lengths then Mounted on Rail that is itself screwed onto each of the Elbows interior cheeks. Bellows custom designed duct work with turning vanes in the elbows for a dry tower leading to a main gas blower inlet. Included in this group is a noise-reducing acoustical turning vane for those systems which require quiet operating systems.

Minimize use of square elbows. Turning Vane is used to turn the air flow in 90 degree Square Elbows on Rectangular Duct jobs. The total assembly is 66 diameter and 749-58 long.

To assemble cut vane and rail to size. If your duct system requires 90 degree ells insist that both inside and outside throats be radiused. Here is a close up of this particular turning vane design.

RETURN DUCT SYSTEMS. Cost of Leakage Duct Geometry and Leakage kwh Year Hours 8520 eff Q FTP Year Cost fan CostYear system first year operating cost Q fan system volume flow rate cfm FTP system total operating pressure in wg HoursYear number of hours the system operates in one year kwh cost of energy eff fanmotor drive combined efficiency 8520 conversion. Increasing the number of vanes neither reduced the pressure drop further nor did it.

Duct Design Fundamentals Static Pressure ps Measure of the static energy of air flowing Air which fills a balloon is a good example of static pressure Equally exerted in all directions The atmospheric pressure of air is a static pressure 14696 psi at sea level. 91 Distributed Return. While the turning vane surfaces do add a small amount of friction the amount of energy lost to friction from the vanes is very little compared to the energy lost in the impact resulting from the airflow taking an abrupt.

When mechanical engineers contractors or the actual manufacturers of ductwork systems are searching for information about HVAC turning vanes performance specifications installation etc. Gooseneck hood cowl back draft damper. The efficiency of Turning Vanes in Square Elbows is understanding that the Width of a duct is greater in the turn.

A comprehensive duct layout indicating sizes design airflows pressure class and routing of the duct system. Add turning vanes to this ell and impact to the TEL is only about 10. The outer half of the flow entering the elbow fig.

This pressure reduction could yield significant fuel savings compared to an engine or generator without a turning vane. 84 Spider System 85 Radial System. Rectangular Duct Radius Elbow with Turning Vanes with varying numbers fro 0 to 3.

Mechanical engineers who are searching for reliable components within an HVAC system for commercial projects will often do research to determine the best possible products to be used. The duct work assemblies are fabricated from 316L stainless steel and designed for temperatures up to 150F. Turning vanes assist the airflow in making a smoother and more gradual change in direction resulting in less of an impact and thus less force transferred as airflow velocity.

92 Central Return. 87 Rules of Duct Design ACCA Manual D Residential Duct Systems 90. 2 which convert the circular inlet duct into a rectangle.

Across the 90-degree duct with a single turning vane showing ranges of 5070 reduction in overall pressure drop across the duct. The inlet duct is circular figs. Yes there really is a turning vane industry though its more of a subset of the HVAC system design industry which is in and of itself pretty large.

THE SUPPLY DUCT SYSTEM. Entry taps conical versus straight taps etc. Assembled Vane Rail minimizes turbulence in the ductwork The Vane Rail has self aligning tabs for easy vane installation.

The duct pressure rating the pressure to apply during the duct leakage test and the allowable cfm100 sqft. Ceiling square type as specified indicate flow direction. Turning Vane are manufactured from 26-gauge galvanized steel.

Vane Systems We offer various options for directing air flow around elbows in duct systems. Normally turning vanes dampers and filters would prevent you from traveling very far. Nordfab Quick-Fit Ducting is easy fast to install.

When these two components are assembled you will have the turning vane assembly 4 which then gets inserted into the elbow or fitting. 1 and 2 and is followed by conical fairings fig. For technical drawings and 3-D models click on a part number.

Provide turning vanes in square elbows of supply ductwork. Rail has mounting tabs to hold vanes. 81 Extended Plenum Systems.

The impact of the turning vanes has a lot to do with both the geometry of the fitting and the velocity of the air moving through it.

Static Pressure In Hvac Systems

Turning Vanes For Better Hvac Duct Performance Hvac Turning Vanes Rail

Turning Vanes Sheet Metal Journal

Rectangular Duct Elbow Radius With Turning Vanes Youtube

Online Searches Or Duct Turning Vanes Often First Step For Engineers Hvac Turning Vanes Rail

Turning Vanes Necessary Component Or Efficiency Reduction Device The Building Engineer

Turning Vanes And Duct Elbows Part 2 A Field Perspective On Engineering

0 comments

Post a Comment